JPI7S-15-99 Brides classe 300

La bride est une sorte de pièce de raccordement qui peut connecter des tuyaux, des vannes et des équipements. Les avantages des brides incluent : 1. Bonne flexibilité : la connexion à bride est facile à démonter et à régler, ce qui est pratique pour l'entretien et le remplacement de l'équipement. 2. Bonne étanchéité : Les joints de bride peuvent utiliser différents joints ou joints pour répondre aux différentes exigences de fluide et de pression, et avoir une bonne étanchéité. 3. Forte capacité de charge de pression : Les joints à bride peuvent résister à de fortes pressions internes et externes, ce qui les rend adaptés aux environnements de travail difficiles tels que les températures élevées, les pressions élevées et la corrosion. 4. Haute fiabilité : étant donné que la connexion à bride est reliée par des boulons et des écrous, elle peut assurer la fermeté de la connexion, améliorant ainsi la stabilité et la fiabilité des équipements et des pipelines. 5. Forte adaptabilité : les joints à bride peuvent être sélectionnés parmi une variété de matériaux, de tailles et de spécifications en fonction des besoins, et peuvent s'adapter à divers environnements de travail et exigences.

The JPI7S-15-99 Class 300 flanges manufacturing method has countless blessings and characteristics:

High Quality: The manufacturing technique of JPI7S-15-99The manufacturing technique of JPI7S-15-99 Class 300 flanges provides a number of benefits and characteristics:

High-quality materials: The flanges are produced the usage of magnificent materials such as carbon metal or stainless steel, making sure sturdiness and resistance to corrosion.

Accurate dimensions: The manufacturing technique ensures that the flanges are manufactured with particular dimensions, permitting for suitable suit and compatibility with otherThe JPI7S-15-99 Class 300 flanges manufacturing system presents countless blessings and showcases sure characteristics. Here are some of them:

High-quality production: The manufacturing technique ensures that JPI7S-15-99 Class 300 flanges are manufactured with excessive precision and foremost quality. This lets in for dependable overall performance and sturdiness of the flanges.

Compliance with standards: The manufacturing system follows the JPI7S-15-99 fashionable for Class 300 flanges. This ensures that the flanges meet the required specs and can be used in a vast vary of functions besides any compatibility issues.

Thorough checking out and inspection: The manufacturing technique consists of rigorous checking out and inspection processes to make sure that the flanges meet the essential requirements and fantastic requirements. This helps in handing over defect-free merchandise to the customers.

Efficient manufacturing techniques: The manufacturing technique makes use of environment friendly manufacturing techniques, such as superior machining and fabrication methods. This permits for quicker manufacturing and ensures that the flanges are manufactured with utmost accuracy.

Material options: The manufacturing procedure permits for the use of a number materials, such as carbon steel, stainless steel, and alloy steel, based totally on the particular necessities of the customers. This affords flexibility in phrases of fabric selection, enabling the flanges to be appropriate for exclusive working conditions.

Corrosion resistance: The flanges produced thru this technique are designed to be corrosion resistant, making them appropriate for use in environments the place publicity to moisture, chemicals, or different corrosive components is likely.

Wide vary of sizes: The manufacturing manner can accommodate the manufacturing of JPI7S-15-99 Class 300 flanges in a broad range of sizes, from small to giant diameters. This makes the flanges appropriate for numerous industrial applications.

Customization options: The manufacturing technique lets in for customizable elements and specs primarily based on the precise necessities of the customers. This ensures that the flanges can be tailor-made to meet the special desires of one of a kind projects.

Overall, the JPI7S-15-99 Class 300 flanges manufacturing method affords a mixture of quality, precision, and flexibility, making it a dependable desire for a number of industrial applications.

-99 Class 300 flanges manufacturing method has countless blessings and characteristics:

High Quality: The manufacturing technique of JPI7S-15-99The manufacturing technique of JPI7S-15-99 Class 300 flanges provides a number of benefits and characteristics:

High-quality materials: The flanges are produced the usage of magnificent materials such as carbon metal or stainless steel, making sure sturdiness and resistance to corrosion.

Accurate dimensions: The manufacturing technique ensures that the flanges are manufactured with particular dimensions, permitting for suitable suit and compatibility with otherThe JPI7S-15-99 Class 300 flanges manufacturing system presents countless blessings and showcases sure characteristics. Here are some of them:

High-quality production: The manufacturing technique ensures that JPI7S-15-99 Class 300 flanges are manufactured with excessive precision and foremost quality. This lets in for dependable overall performance and sturdiness of the flanges.

Compliance with standards: The manufacturing system follows the JPI7S-15-99 fashionable for Class 300 flanges. This ensures that the flanges meet the required specs and can be used in a vast vary of functions besides any compatibility issues.

Thorough checking out and inspection: The manufacturing technique consists of rigorous checking out and inspection processes to make sure that the flanges meet the essential requirements and fantastic requirements. This helps in handing over defect-free merchandise to the customers.

Efficient manufacturing techniques: The manufacturing technique makes use of environment friendly manufacturing techniques, such as superior machining and fabrication methods. This permits for quicker manufacturing and ensures that the flanges are manufactured with utmost accuracy.

Material options: The manufacturing procedure permits for the use of a number materials, such as carbon steel, stainless steel, and alloy steel, based totally on the particular necessities of the customers. This affords flexibility in phrases of fabric selection, enabling the flanges to be appropriate for exclusive working conditions.

Corrosion resistance: The flanges produced thru this technique are designed to be corrosion resistant, making them appropriate for use in environments the place publicity to moisture, chemicals, or different corrosive components is likely.

Wide vary of sizes: The manufacturing manner can accommodate the manufacturing of JPI7S-15-99 Class 300 flanges in a broad range of sizes, from small to giant diameters. This makes the flanges appropriate for numerous industrial applications.

Customization options: The manufacturing technique lets in for customizable elements and specs primarily based on the precise necessities of the customers. This ensures that the flanges can be tailor-made to meet the special desires of one of a kind projects.

Overall, the JPI7S-15-99 Class 300 flanges manufacturing method affords a mixture of quality, precision, and flexibility, making it a dependable desire for a number of industrial applications.

Nominal Tuyau Taille |

Dehors Dia.de Brides |

Diamètre d'alésage |

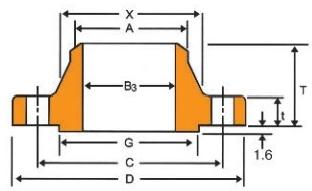

Diamètre du moyeu à biseau UN |

Dia.of Hub à Base |

Dia.de Soulevé Affronter |

Épais de Brides |

Rayon de Filet |

|||||||||||

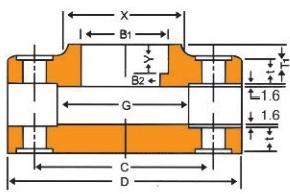

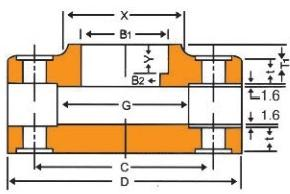

Glisser sur Prise B1 |

Joint de recouvrement B2 |

Soudage-cou, douille B₃ |

||||||||||||||||

JPI |

ANSI |

|||||||||||||||||

UN |

B |

D |

JPI |

ANSI |

JPI |

ANSI |

SCH40 |

SCH80 |

SCH160 |

SCH40 |

SCH80 |

SCH160 |

JPI |

ANSI |

X |

g |

t |

R |

15 20 25 |

h % 1 |

95 117 124 |

22.2 27,7 34,5 |

22.4 27,7 34,6 |

23,4 28,9 35,6 |

22,9 28,2 35.1 |

16,1 21,4 27.2 |

14,3 19,4 25,0 |

12,3 16,2 21.2 |

15,8 20,9 26.6 |

13,9 18,8 24.3 |

11,8 15,6 20.7 |

21,7 27,2 34,0 |

21,3 26,7 33,5 |

38,1 47,8 53,8 |

35,1 42,9 50,8 |

14,2 15,7 17.5 |

3 3 3 |

(32) 40 50 |

(14) 1% 2 |

133 155 165 |

43.2 49.1 61.1 |

43.2 49,6 62,0 |

44,3 50,4 62,7 |

43,7 50,0 62,5 |

35,5 41,2 52,7 |

32,9 38,4 49,5 |

29,9 34,4 43.1 |

35,1 40,9 52,5 |

32,5 38,1 49.3 |

29,5 34,0 42,9 |

42,7 48,6 60,5 |

42,2 48,3 60,5 |

63,5 69,9 84.1 |

63,5 73,2 91,9 |

19,1 20,6 22.4 |

5 6 8 |

65 80 (90) |

2% 3 (3 %) |

190 210 229 |

77,1 90,0 102.6 |

74,7 90,7 103.4 |

78,7 91,6 104.1 |

75,5 91,4 104.2 |

65,9 78,1 90.2 |

62,3 73,9 85,4 |

57,3 66,9 76,2 |

62,7 77,9 90.1 |

59,0 73,7 85,5 |

54,0 66,7 |

76,3 89,1 101.6 |

73,2 88,9 101.6 |

100,1 117,5 133.4 |

104,6 127,0 139,7 |

25,4 28,4 30.2 |

8 dix dix |

100 (125) 150 |

4 (5) 6 |

254 279 318 |

115,4 141,2 166.6 |

116,1 143,8 170.7 |

116,9 143,0 168.4 |

116,9 144,6 171,5 |

102,3 126,6 151,0 |

97,1 120,8 143.2 |

87,3 108,0 128,8 |

102,3 118,2 154.2 |

97,2 122,3 146.3 |

87,3 109,6 131,8 |

114,3 139,8 165.2 |

114,3 141,2 168.4 |

146,1 177,8 206.2 |

157,2 185,7 215.9 |

31,8 35,1 36,6 |

11 11 13 |

200 250 300 |

8 dix 12 |

381 444 521 |

218,0 269,5 321.0 |

221,5 276,4 327.2 |

219,5 271,7 322.8 |

222,3 277,4 328.2 |

199,9 248,8 297,9 |

190,9 237,2 283.7 |

170,3 210,2 251.9 |

202,7 254,5 303.2 |

193,7 242,9 288,9 |

173,1 215,9 257.2 |

216,3 267,4 318,5 |

219,2 273,1 323,9 |

260,4 320,8 374,7 |

269,7 323,9 381.0 |

41,1 47,8 50,8 |

13 13 13 |

350 400 450 |

14 16 18 |

584 648 710 |

358,1 409,0 460,0 |

359,2 410,5 461.8 |

360,2 411,3 462.4 |

333,4 381,0 428.6 |

317,6 363,6 409.6 |

284,2 325,4 366,8 |

333,3 381,0 428.7 |

317,5 363,6 409.6 |

284,2 325,5 366.7 |

355,6 406,4 457.2 |

355,6 406,4 457.2 |

425,5 482,6 533.4 |

412,8 469,9 533.4 |

53,8 57,2 60,5 |

13 13 13 |

|

500 600 |

20 vingt-quatre |

775 914 |

511.0 613.0 |

513.1 616.9 |

514.4 616.0 |

477.8 574.6 |

455.6 547.8 |

408.0 490.6 |

477.8 574.8 |

455.6 547.7 |

408.0 490.6 |

508.0 609.6 |

508.0 609.6 |

587.2 701.5 |

584.2 692.2 |

63,5 69,9 |

13 13 |

|

Longueur à travers le moyeu |

Profondeur de Prise |

Forage |

Dia of Raised Face for Ring Joint |

Diamètre de lancement ou anneau & Rainure |

Anneau

Non. |

Type RTJ |

Poids approximatif (kg) |

Nominal Tuyau Taille |

||||||||||

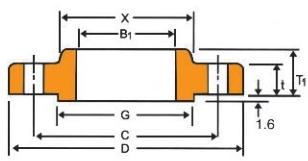

Filetage à douille à enfiler |

Lap

Joint |

Soudure Cou |

Jour du cercle de boulons |

Nombre de Magasin |

Diamètre du boulon Trou |

Profondeur de Rainure |

Largeur de Rainure |

Rayon de Rainure |

WN |

S.0 |

SW |

BL |

||||||

T; |

T2 |

J |

ET |

C |

N |

K(min) |

P |

ET |

F |

4 |

UN |

B |

||||||

22.2 25,4 27,0 |

22,2 25,4 27,0 |

52,4 57,2 61,9 |

9,5 11,1 12.7 |

66,5 82,6 88,9 |

4 4 4 |

16 19 19 |

51.0 63.5 70.0 |

34,14 42,88 50,80 |

R11 R13 R16 |

5,56 6,35 6.35 |

7.14 8.74 8.74 |

0,8 0,8 0,8 |

0,80 1,25 1,58 |

0,65 1,10 1,35 |

0,67 1,12 1.39 |

0,65 1,09 1.38 |

15 20 25 |

c % 1 |

27,0 30.2 33.3 |

27,0 30,2 33.3 |

65,1 68,3 69,8 |

14,3 15,9 17.5 |

98,6 114,3 127,0 |

4 4 8 |

19 22 19 |

79,5 90,5 108 |

60,32 68,28 82,55 |

R18 R20 R23 |

6,35 6,35 7,92 |

8,74 8,74 11.91 |

0,8 0,8 0,8 |

2,05 2,93 3.40 |

1,69 2,54 2,92 |

1,74 2,60 3.02 |

1,82 2,70 3.18 |

(32) 40 50 |

(114) (1 pour 2 |

38.1 42,9 44,5 |

38,1 43,9 44,5 |

76.2 79.4 81.0 |

19,0 20,6 22.2 |

149.4 168.1 184.2 |

8 8 8 |

vingt-deux vingt-deux vingt-deux |

127 146 159 |

101,60 123,82 131,78 |

R26 R31 R34 |

7,92 7,92 7,92 |

11,91 11,91 11.91 |

0,8 0,8 0,8 |

5.10 7.01 8.71 |

4,24 5,94 7,90 |

4.43 6.21 |

4,86 6,90 8,79 |

65 80 (90) |

2% 3 (3 %) |

47.6 50.8 52.4 |

47.6 50.8 52.4 |

85,7 98,4 98,4 |

23.8 23.8 27.0 |

200.2 235.0 269.7 |

8 8 12 |

vingt-deux vingt-deux vingt-deux |

175 210 241 |

149.22 180.98 211.12 |

R37 R41 R45 |

7,92 7,92 7,92 |

11,91 11,91 11.91 |

0,8 0,8 0,8 |

11.3 15.1 19.6 |

9.71 12.4 16.2 |

11.6 15.5 21.2 |

100 (125) 150 |

4 (5) 6 |

|

61.9 66.7 73.0 |

61.9 95.3 101.6 |

111.1 117.5 130.2 |

31.8 33.3 39.7 |

330.2 387.3 450.9 |

12 16 16 |

26 29 32 |

302 356 413 |

269.88 323.85 381.00 |

R49 R53 R57 |

7,92 7,92 7,92 |

11,91 11,91 11.91 |

0,8 0,8 0,8 |

30.3 44.3 64.1 |

24.8 35.9 51 |

34.5 53.9 78.9 |

200 250 300 |

8 dix 12 |

|

76.2 82.6 89.9 |

※111.3 ※120.7 ※130.0 |

142.9 146.0 158.8 |

41.3 44.5 49.2 |

514.4 571.5 628.7 |

20 20 24 |

32 35 35 |

457 508 575 |

419.10 469.90 533.40 |

R61 R65 R69 |

7,92 7,92 7,92 |

11,91 11,91 11.91 |

0,8 0,8 0,8 |

88.3 113 138 |

70.1 90.4 109 |

106 139 175 |

350 400 450 |

14 16 18 |

|

95.2 106.4 |

※149.7 ※152.4 |

161.9 168.3 |

54.0 63.5 |

685.8 812.8 |

.24 24 |

35 42 |

635 749 |

584.20 692.15 |

R73 R77 |

9.52 11.13 |

13.49 16.66 |

1.5 1.5 |

169 248 |

136 204 |

222 340 |

500 600 |

20 vingt-quatre |

|

Notre usine

Masquage de matières premières

Examen de laboratoire

Forgeage et forgeage et pressage

Traitement mécanique

Honneur à la qualification d'entreprise